Petrography is a distinct branch of petrology, which focuses on detailed study and analysis of rocks. This subject precisely deals with the relationship between mineral content and textural relationships existing within rocks. A person who studies this relationship is referred to as petrographer. On the other hand, classification of rocks is done based on their petrographic analysis. A detailed study invariably involves field notes and macro description of specimens. To conduct this detailed study, petrographers depend largely on petrographic microscope.

Performing this special kind of rock study becomes necessary on instances like premature failing of a concrete structure. Even in cases of other problems cropping up a construction project site the test is conducted. A thorough petrographic study helps determining cause of the problem. The study is also performed to determine whether a concrete structure can be rehabilitated or requires replacement.

Study of petrography provides information on contrasting aspects like fine & coarse aggregates, cement paste, air void system and condition of wearing surface concrete, etc. To conduct this test there has to be a proficient team of highly trained experts. Firms that provide this specialized service employ proficient engineers and scientists to deliver state-of-the-art service. As such, a host of competent agencies has emerged lately across Singapore, catering to this sector. The range of players is efficiently catering to an ever increasing customer base covering a vast geographical region on earth. Providing dependable service at reasonable cost is the key to success for these agencies.

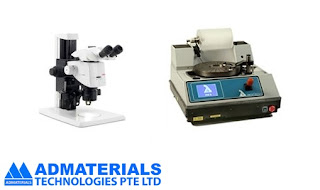

The range of specialized service providers not only invests on hiring expert professionals but allocates huge funds on procuring impressive tools and gadgets based on the latest version of technology. These agencies are adequately equipped to conduct the full range of petrographic tests including BS 812 – Pt 104, BS 7943, BS EN 932 – 3, SS EN 12620, ASTM C295 for concrete aggregates, and ASTM C856 for hardened concrete.